Janome Servo Press Dealers Suppliers in Chennai | Flextech Automation

Janome Servo Press Dealers Suppliers in Chennai– Flextech Automation facilitates a wide range of robot products including Janome Servo Press Dealers Suppliers in Chennai

Janome Servo Press Dealers Suppliers in Chennai – Flextech Automation, We are notable exporter, manufacturer and supplier of all new range of Janome Scara Robots in Chennai. Industrial robot is a manipulator designed to move materials, parts and tools, and perform a variety of programmed tasks in manufacturing and production settings in Chennai. Industrial Janome Scara robots are reshaping the manufacturing industry. They are often used to perform duties that are dangerous or unsuitable for human workers.

Factory robots scara are perfect for factories looking for maximum value without giving up performance. They are used for applications such as mechanical or electrical assembly, pick and place, kitting, dispensing and much more. Flextech Automation’s are the robot of choice when price/performance is critical. Flextech Automation arms come with a 400, 600, 700 mm arm length and Clean room models are available. With outstanding cycle times, industry leading ease of use and of course reliability, Flextech’s are the top robots of industrial choice in Chennai.

Janome Scara Robot Market Dynamics in Chennai

The Scara configuration is one of its kinds and is utilized for different types of material handling tasks in the production plant. Scara Robots have selected methods for small robotic assembly applications. The global Scara Robot market is driven by the growing need for mass production with reduced operation cost and reduce human efforts and errors in the production process.

The necessity of automation and IoT-based smart solutions in several industries for quality product manufacturing, and wide acceptance of industry 4.0 and allowing technologies in industries are impelling market growth in the upcoming period. However, due to high expenditure on the implementation of Scara robots are restraining the market growth at the global level.

Desktop, Cartesian and Scara Robots

Building on technology refined through years of precision sewing machine development, we forge ahead in the high function industrial equipment field. Always on the cutting edge in manufacturing, we devote ourselves to offering the finest quality in everything we do from product development to after sales service.

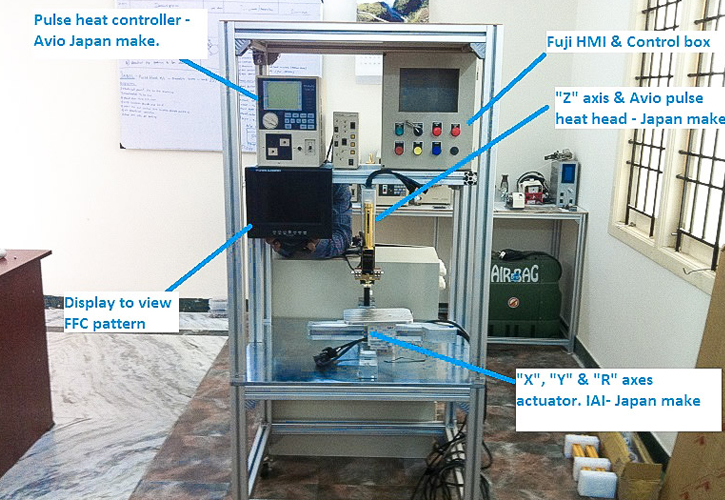

Our main products, namely servo presses and desktop, Cartesian and Scara robots are valued by customers for precision work in a variety of manufacturing fields, including the automotive parts, IT and electronics industries.

MAIN FEATURES

- Built-in Simple PLC Function

- Field bus Compatibility

- LAN (Ethernet) port included as standard equipment

- Teaching pendant features 11 different display languages

- Highly compatible with vision system installation

- Control up to 4 axes and 2 external motors with the Auxiliary Axis Function (optional)

- Easy Program Teaching

- High speed cycle times to maximize part throughput

- Low cost in robot industry

- Low residual vibration due to powerful proprietary servo system design

The JS3 Series offers the convenience of a multilingual teaching pendant, optional PC software for teaching and editing programs, a LAN cable port, USB memory port, a dedicated port and optional solenoid valve for gripper (hand) connection, 6 different field networks to choose from and more. Add up to 2 additional motors to serve as auxiliary axes which you can control together with the robot axes. Internal air piping and wiring for tool connection help to save space and minimize interference.